In the evolving field of electronic engineering, staying abreast of the best practices regarding electronic test equipment is not just beneficial—it’s essential. Engineers need to know their tools as well as they understand their craft. Read on to find out what engineers should know about electronic test equipment.

The Spectrum of Equipment

Engineers often start with a multimeter, a versatile tool that measures voltage, current, and resistance. However, the depth of electronic test equipment goes far beyond this. Familiarity with spectrum analyzers, which provide insights into the frequency spectrum of signals, or network analyzers, which assess network components, is indispensable. Each piece of equipment, no matter how sophisticated, serves the purpose of pinpointing issues and verifying electronic operations, which are foundational to successful engineering projects.

The Significance of Calibration

The accuracy of any measurement is only as reliable as the calibration of the test equipment used. Engineers must ensure their instruments are calibrated regularly against industry standards. This not only guarantees the validity of measurements but also maintains the integrity of the development process. Calibration can sometimes be overlooked, but its importance cannot be overstated; it underscores the credibility of any testing procedure.

Advanced Features

Modern test equipment comes loaded with features that can simplify complex testing scenarios. Understanding these features, such as automated testing sequences, programmable settings, and data logging capabilities, can save time and enhance the efficiency of test procedures. Engineers should take the time to master these features to leverage the full potential of their test equipment.

Safety Practices for Electronic Test Equipment

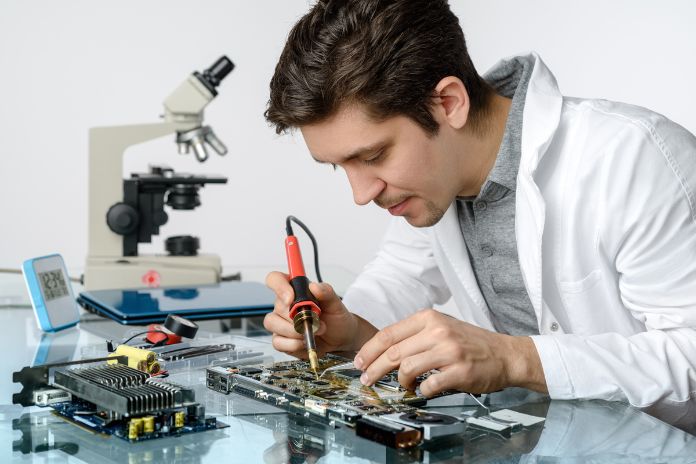

There are some essential safety practices for electronic test equipment usage that engineers should know. Working with electronic test equipment involves exposure to electric currents and voltages that can be dangerous. Proper safety practices include using insulated tools, understanding the equipment’s operation limits, and adhering to proper grounding techniques. In addition, engineers should be familiar with emergency procedures in case of an electrical accident, ensuring not just the safety of the equipment but also of the individuals using it.

Now that you understand what engineers should know about electronic test equipment, you can appreciate the profound impact of these devices on the field of engineering. The right knowledge and application of this equipment not only enhances precision in testing and diagnostics but also ensures the safety and effectiveness of electronic innovations. By staying informed and adhering to these principles, engineers can maintain the highest standards of quality in their work.